- Home

- Portfolios

- Solar High Mast Light

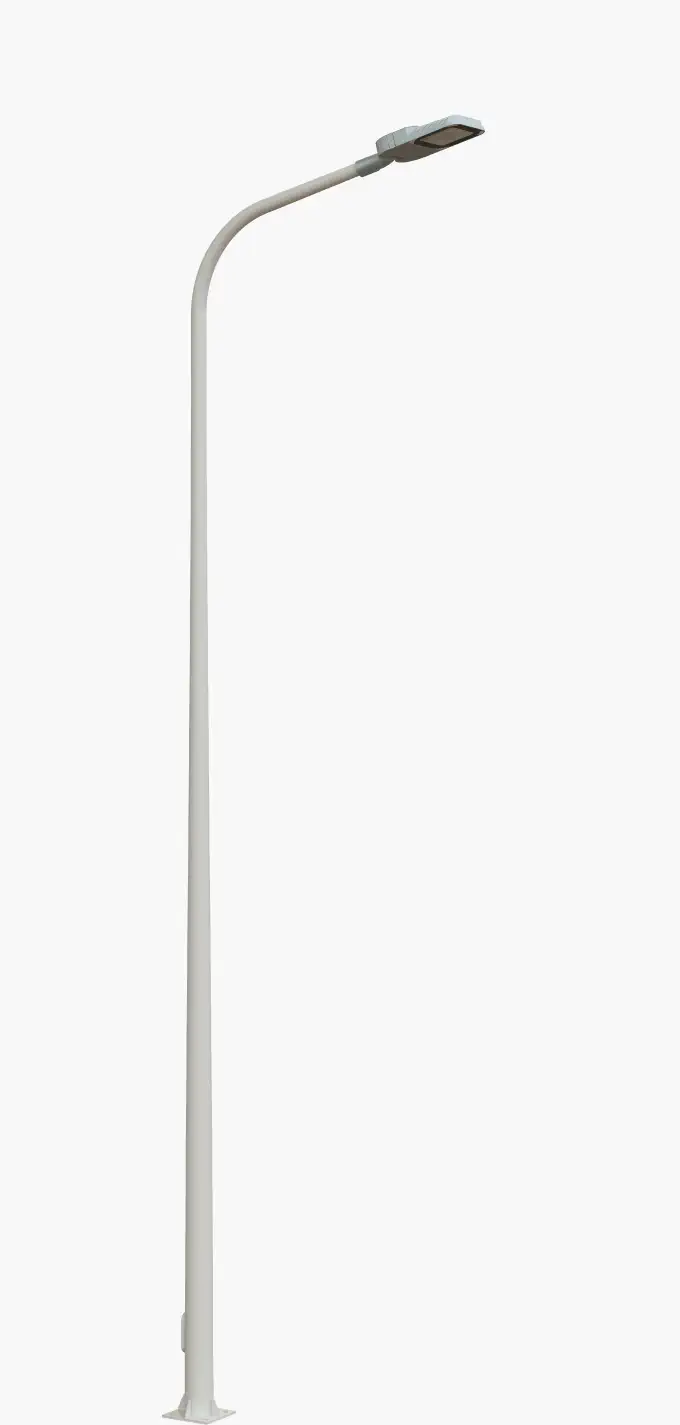

- Solar Mini Mast Light

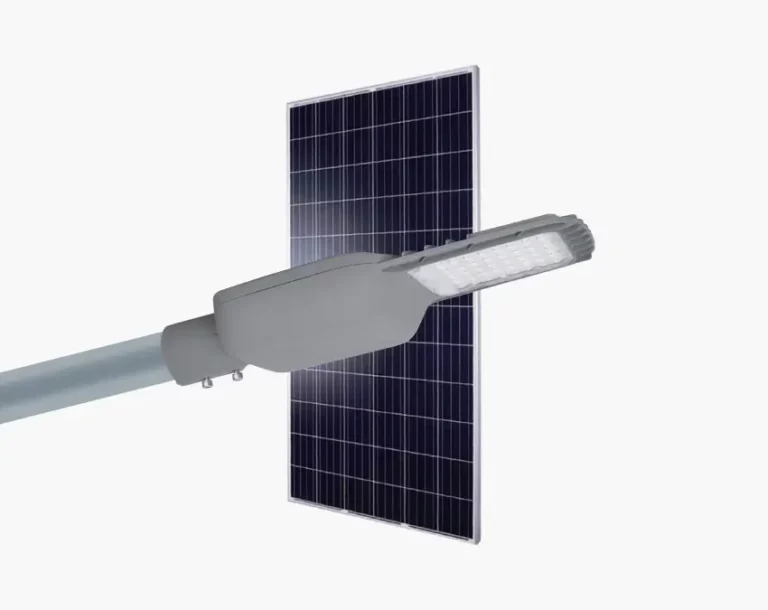

Solar Mini Mast Light

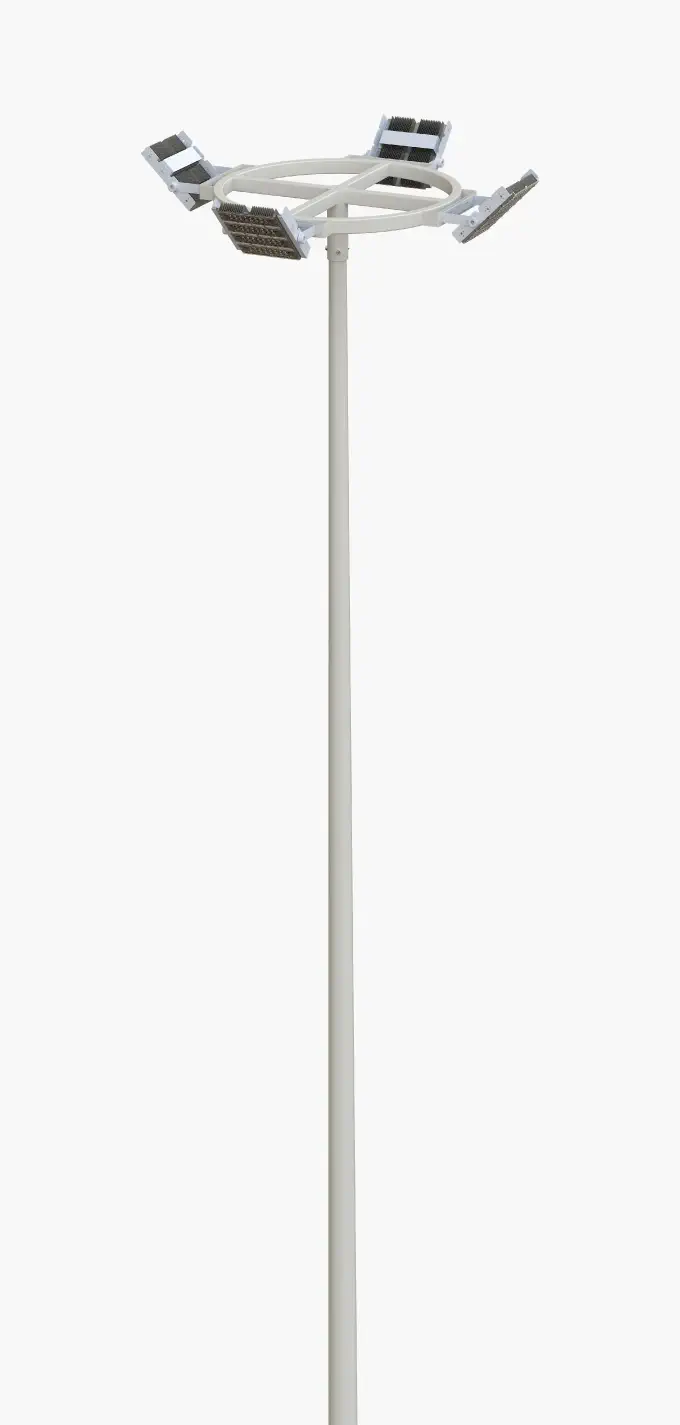

Solar Hight Mast Light

Applications:

- Highway

- Street

- Intersection

- Roundabout

- Parking Lot

- Business District

- Perimeter

- Industrial Zone

- Factory

- Residential Community

- Refugee Camp

Specifications

| Lamp Power | 50W-250W Per Lamp |

| Lamp Qty | 1-6 sets |

| Power Supply | Solar Power |

| Beam Angle | 8°,20°,30°,40°,60°,90°,100°,120° |

| CCT | 3000k-6500k |

| CRI | >70 (>80,>90 optional) |

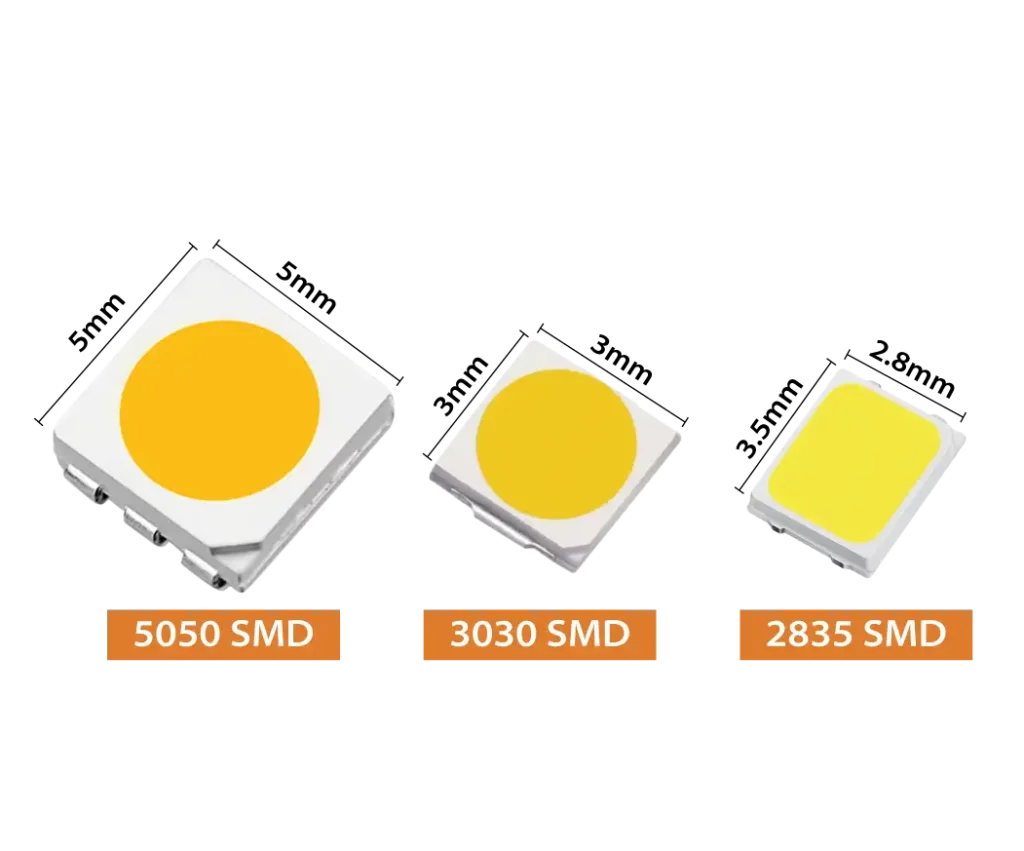

| LED Chip | SMD 5050 |

| Luminous Efficiency | >175lm/w (SMD 5050) |

| Polygonal Mast Pole Height | 8-15 Meters |

| Polygonal Mast Pole Material | Q345b/A572, Q235b/A36 |

| Joint of Mast Poles | Insert Mode, Inner Flange Mode, Face To Face Joint Mode |

| Raising & Lowering System | Optional |

| Wind Resistance Capacity | >160km/h |

| System Life Time | >10 Years |

| IP/IK Rate | IP65 / IK09 |

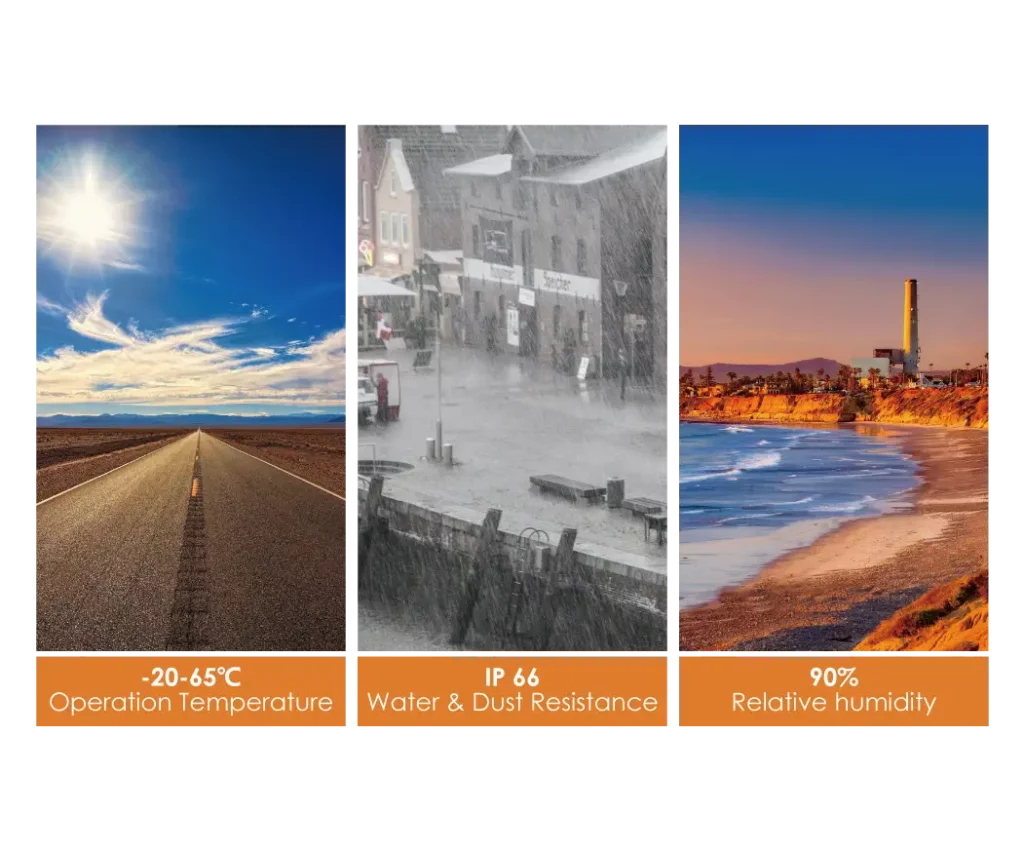

| Working Temperature | -40°C~50°C, 20%~90% RH |

| Accessories | Foundation Kits, Lighting Rod, Climbing Ladder, Rain Cover |

Interior Structure

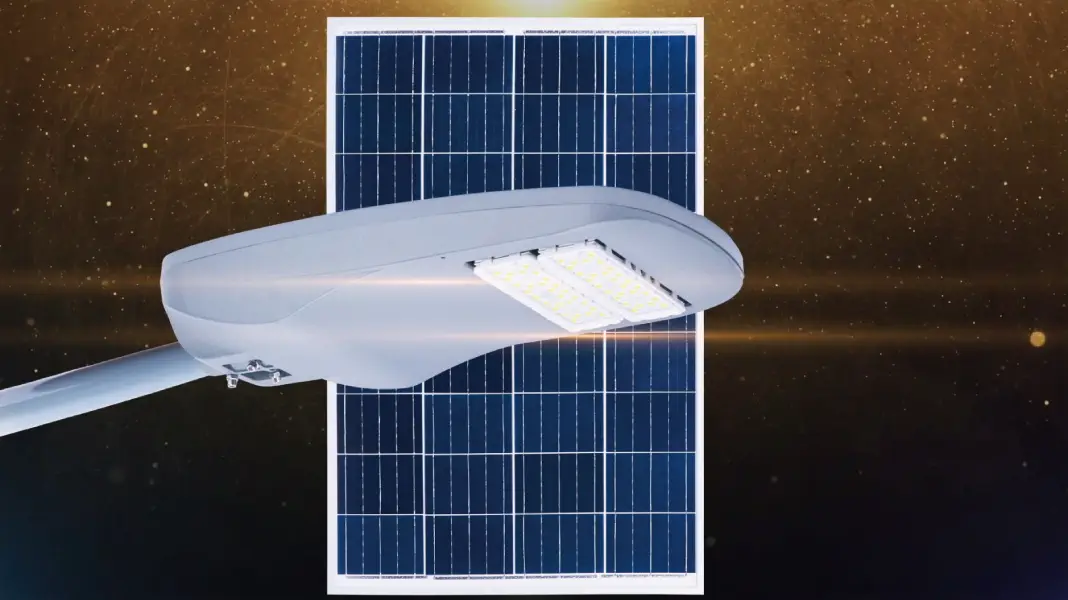

IP67 Extreme Bright LED Modules

Featuring advanced 5050 LED chips with an impressive efficiency of up to 220lm/w...

Featuring advanced 5050 LED chips with an impressive efficiency of up to 220lm/w, this lighting solution delivers extreme brightness and reliable performance. Designed with high-temperature resistance and low thermal resistance, it ensures a longer LED lifespan. The thick aluminum heat sink, combined with a fast heat dissipation module, guarantees optimal performance and durability, while the easy-maintenance design simplifies upkeep.

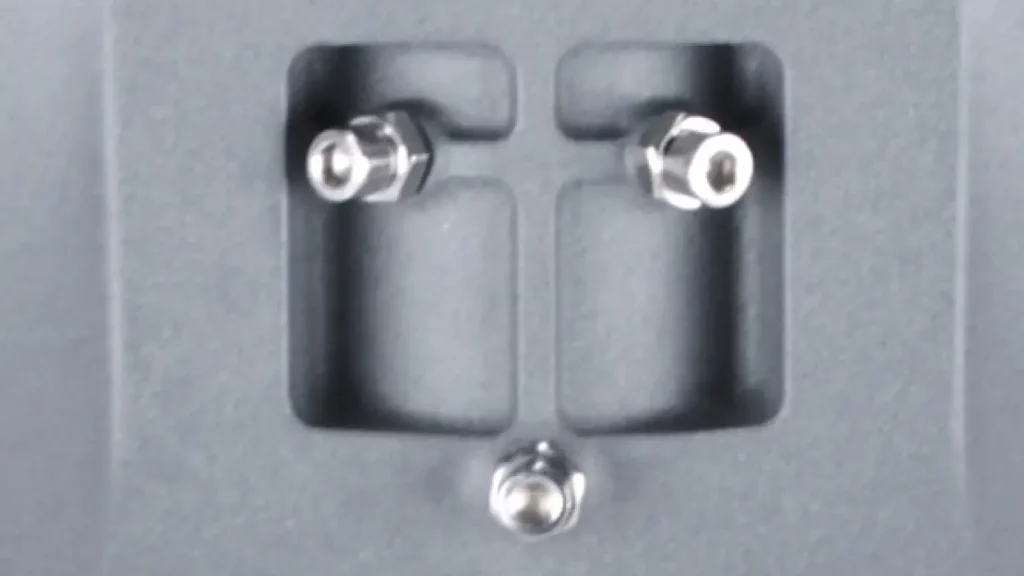

Triangle Strong Designed Screws

The fixture is equipped with triangle strong-designed screws that provide a secure...

The fixture is equipped with triangle strong-designed screws that provide a secure and reliable installation. These specially designed screws prevent the fixture from rotating once mounted, ensuring it remains fixed in place. The triangular shape enhances the grip, offering better torque resistance and stability, even in environments with vibrations or movement. This feature guarantees the long-term safety and proper alignment of the fixture, preventing any accidental shifts or misalignment.

Smart Solar Controller

The Smart Solar Controller offers high efficiency with a smart power-saving mode that...

The Smart Solar Controller offers high efficiency with a smart power-saving mode that optimizes energy use. It operates with constant current and an IP68 rating, ensuring reliable performance even in harsh environmental conditions. This advanced design significantly reduces the light failure rate, providing consistent brightness over time. Additionally, the controller includes multiple protection features that effectively safeguard the battery, enhancing its longevity and ensuring the system's overall durability and safety.

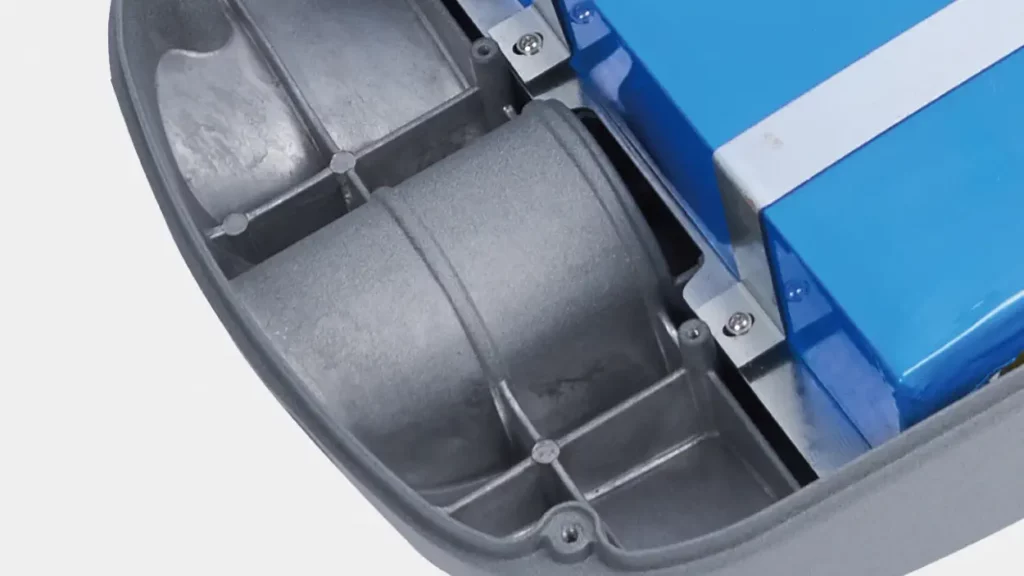

Aluminum Die-casting Fixture

The fixture features a complete die-casting aluminum construction, ensuring...

The fixture features a complete die-casting aluminum construction, ensuring durability and superior heat dissipation. With an IP67 protection rating, it is fully sealed by a waterproof ring, making it resistant to dust and water ingress. This design provides reliable performance even in harsh outdoor environments, ensuring the fixture remains functional and protected from moisture and debris. The robust aluminum housing enhances the fixture’s lifespan and performance, making it an ideal choice for a wide range of applications.

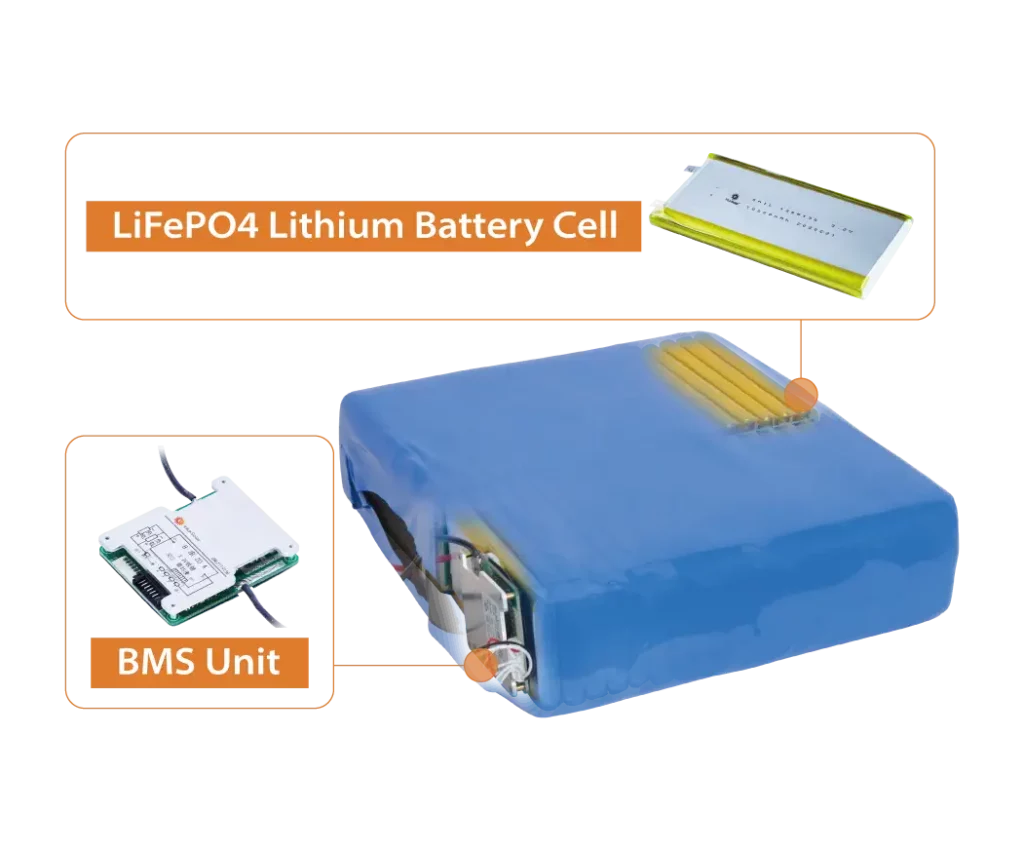

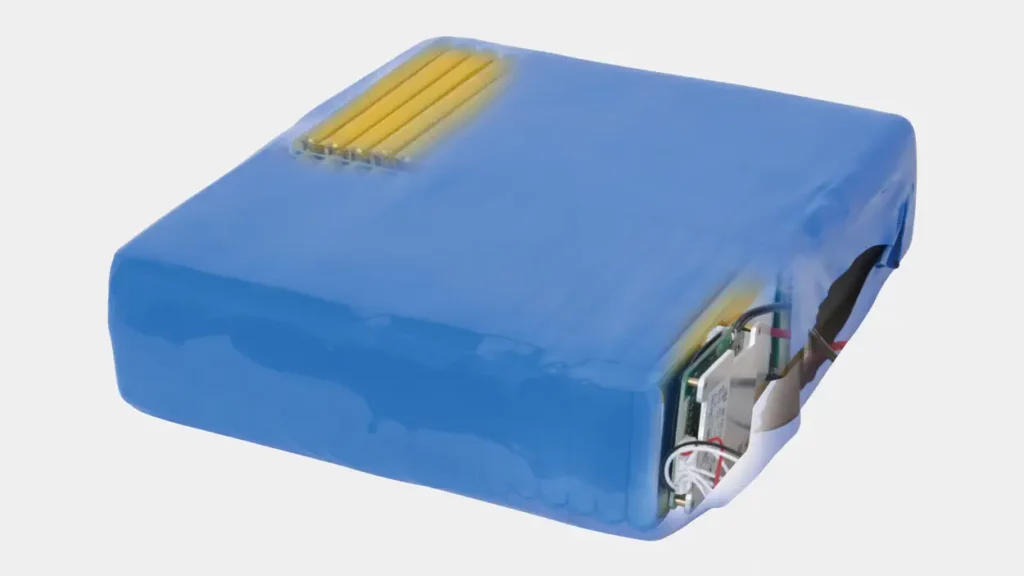

LiFePO4 Lithium Battery

The fixture is equipped with a LiFePO4 lithium battery, known for its impressive lifespan...

The fixture is equipped with a LiFePO4 lithium battery, known for its impressive lifespan of over 10 years. This battery offers excellent high-temperature resistance and exceptional safety performance, ensuring reliable power delivery and enhanced durability. With its long service life, it reduces the need for frequent replacements and provides peace of mind, making it an ideal choice for both residential and commercial applications.

Enhanced Strong Lamp Holder

The fixture features an enhanced strong lamp holder with an IP67 protection rating, sealed by...

The fixture features an enhanced strong lamp holder with an IP67 protection rating, sealed by a waterproof ring to prevent dust and water ingress. Additionally, it is equipped with IK09 impact protection, ensuring resistance to strong impacts and mechanical stresses. This combination of features makes the lamp holder highly durable and ideal for use in harsh environments, providing long-lasting performance and protection against both water and physical damage.

How JAGUAR Benefits Your Project

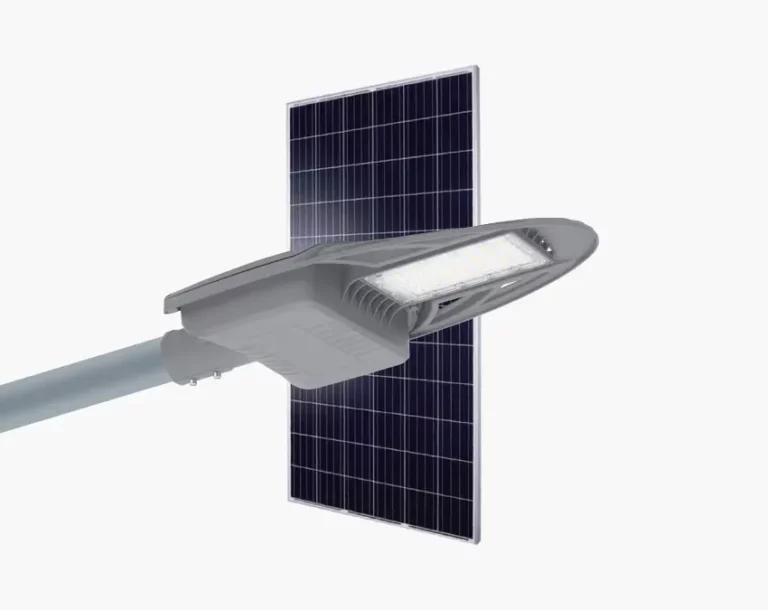

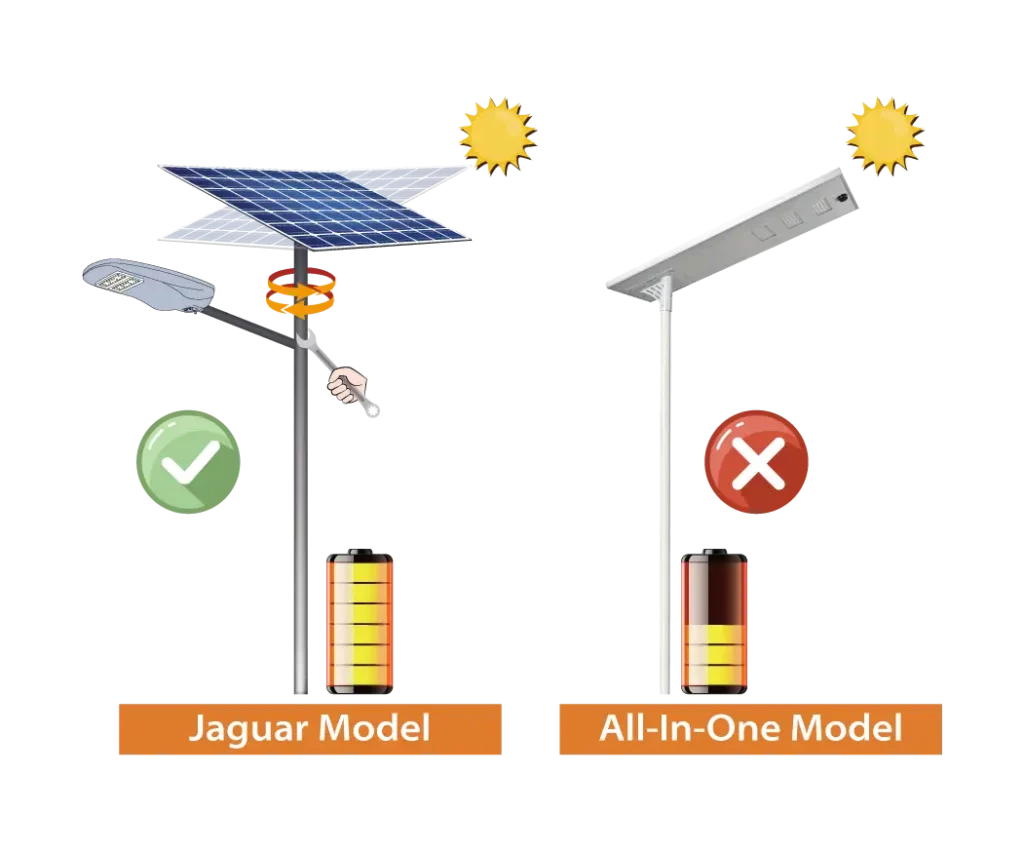

Independent Solar Panel Design Provides Higher Solar Power

Extreme Bright 5050 LED Provides 40% Higher Brightness

10+ Years Lifespan Lithium Battery

Operable Under Harsh Environment

Optional Functions

01

Motion Sensor

The brightness of the display will automatically dim to 30% during periods of inactivity...

The brightness of the display will automatically dim to 30% during periods of inactivity, reducing energy consumption and minimizing distractions. When presence is detected, the brightness will seamlessly return to 100%, ensuring optimal visibility and user comfort. This feature helps to create a balance between power efficiency and convenience, offering a responsive and adaptive experience.

1

02

Adjustable Solar Panel Bracket

An Adjustable Solar Panel Bracket is a versatile mounting solution designed to optimize...

An Adjustable Solar Panel Bracket is a versatile mounting solution designed to optimize the positioning of solar panels for maximum energy efficiency. It allows users to easily adjust the tilt angle and orientation of the panels to capture the most sunlight throughout the day, regardless of seasonal changes or geographical location. Built with durable materials, the bracket is designed to withstand harsh weather conditions while maintaining stability and performance. Ideal for both residential and commercial solar installations, this bracket ensures flexibility and enhances the efficiency of solar energy systems.

2

03

Anti-theft Components

Anti-theft screws and anti-climbing spikes are essential security solutions designed...

Anti-theft screws and anti-climbing spikes are essential security solutions designed specifically for solar panel installations to protect against theft and unauthorized access. Anti-theft screws feature unique tamper-resistant designs, making them nearly impossible to remove without specialized tools, ensuring that solar panels and their mounting systems remain secure even in exposed outdoor environments. Complementing this, anti-climbing spikes act as a physical deterrent, installed on fences or mounting structures to prevent unauthorized climbing or tampering with solar panel systems. Made from durable materials like steel or aluminum, these spikes create a sharp, angled barrier, enhancing perimeter security and protecting solar energy systems in residential, commercial, and industrial settings. Together, these features provide a robust, low-maintenance solution to safeguard valuable solar energy investments.

3

04

Anti-bird Spike

Anti-bird spikes are a humane and effective solution designed to prevent birds from perching...

Anti-bird spikes are a humane and effective solution designed to prevent birds from perching or nesting on rooftops, ledges, fences, and solar panel installations. These spikes are typically made of durable stainless steel or plastic and feature rows of sharp, angled prongs that discourage birds from landing without causing them harm. They are often used on solar panel mounts to protect the panels from bird-related damage, such as nesting debris or droppings, which can obstruct solar panel performance. Easy to install, anti-bird spikes are ideal for residential, commercial, and industrial properties, offering a low-maintenance way to keep solar energy systems secure and functioning at their best.

4

05

Camera

The system can integrate a solar-powered CCTV camera, providing a sustainable...

The system can integrate a solar-powered CCTV camera, providing a sustainable and eco-friendly surveillance solution. By harnessing the power of the sun, these cameras operate independently of traditional power sources, ensuring continuous monitoring without the need for wiring or external electricity. The integration of a solar-powered CCTV camera enhances security for solar panel installations, protecting them from theft or vandalism. These cameras are designed to function efficiently in outdoor environments, with weatherproof housing and motion detection features, offering a reliable surveillance system while reducing energy costs and carbon footprint.

5

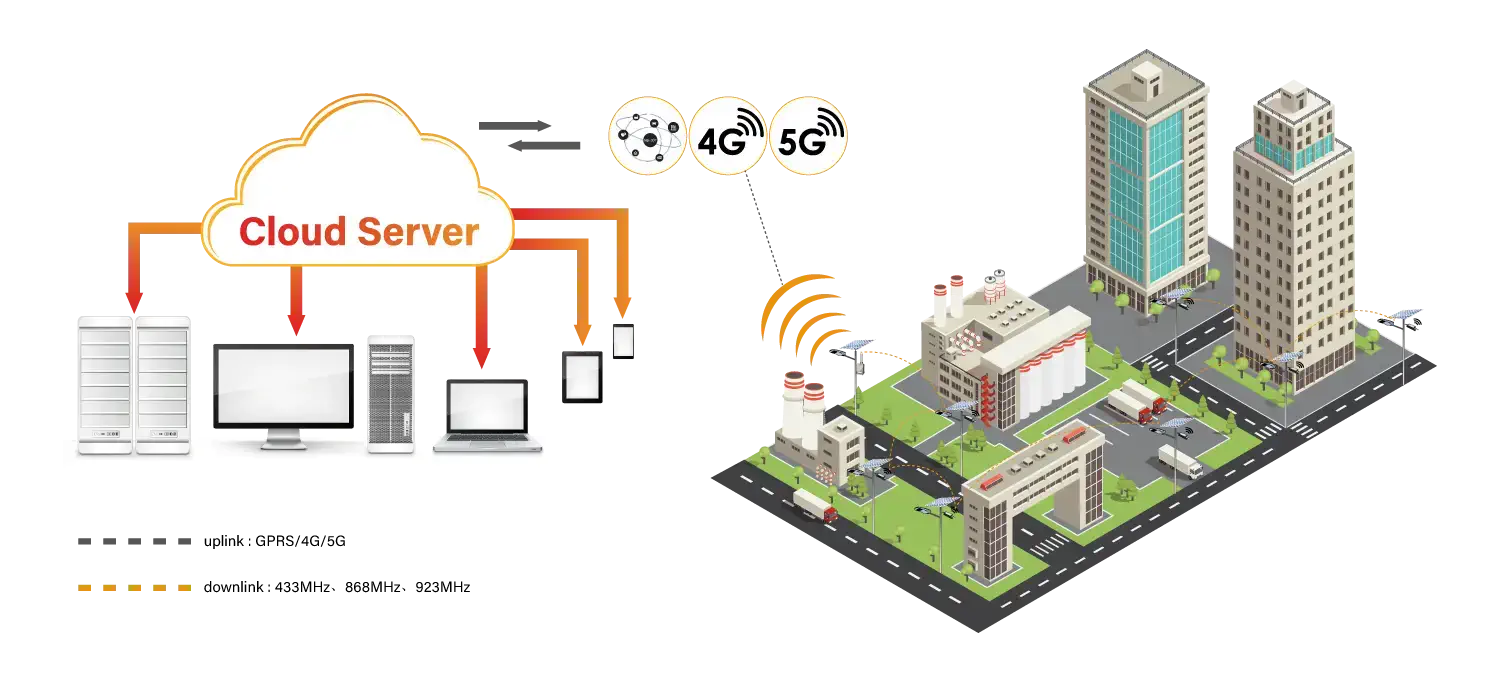

IoT Smart Monitoring System

Based on LoRA, Zigbee, 4G technology, INLUX’s IOT Smart Monitoringl System enables intelligent management of our solar street lights by PC, PAD and Mobile.

GPS Map

Failure Warning

Historical Data Record

Remote Management of Lighting Modes

Authority Management

Remote ON/OFF Switch

Working Condition Monitoring

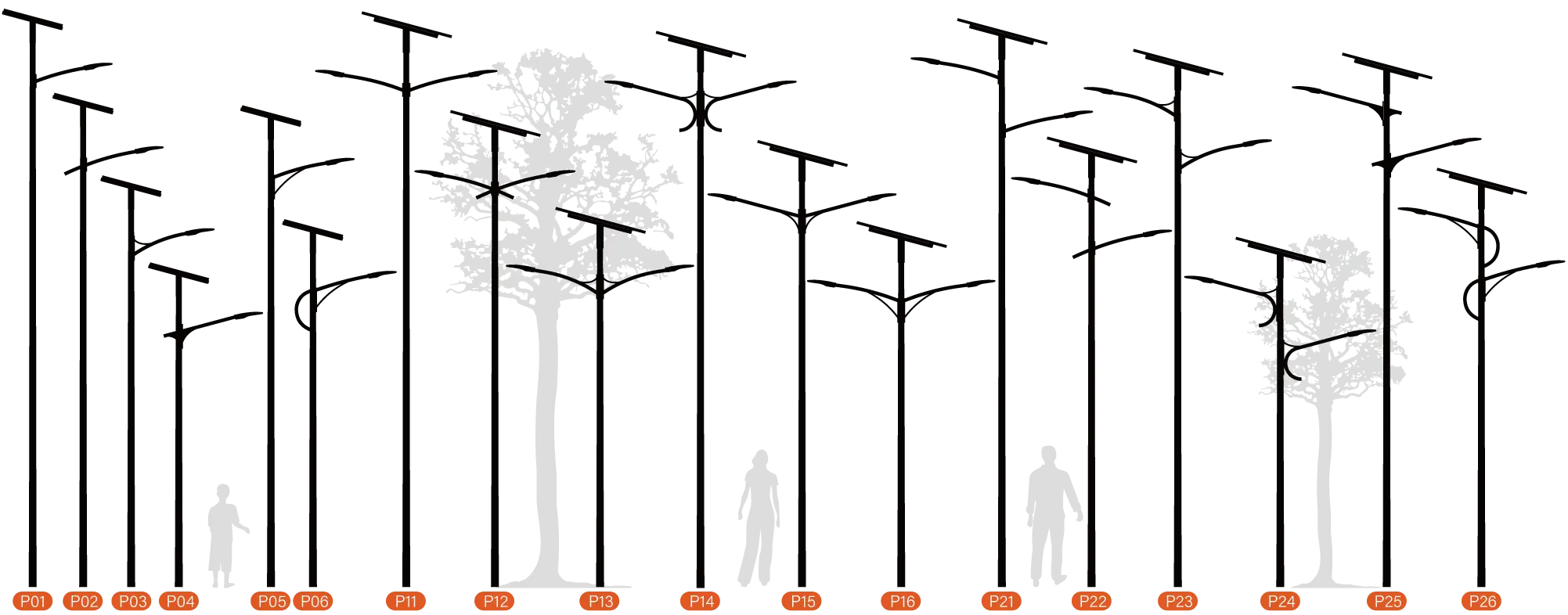

Pole Designs

Installation Methods

Installation instructions video

1

Connect JAGUAR solar light with the solar panel by the plug & play socket.

2

JAGUAR solar light will work automatically according to the preset program.

Product Videos

IP67 Test Jaguar (INL-AIT5) Solar Light

All-In-Two High Power Solar Street Light

INLUXSOLAR Solar Street Light Factory

JAGUAR (INL-AIT5) Installation

See JAGUAR’s Performance Across These Projects