Strict Quality Control

At Inlux Solar, every component used in our outdoor lighting products undergoes rigorous inspection as part of our ISO-certified quality management system, ensuring consistency and reliability. Our high-performance solar streetlights, installed in over 100 countries, continue to shine bright with unmatched durability.

- Home

- Strict Quality Control

Guarantee of Excellent Quality

01

Independent Quality Control Team

We have a dedicated QC team responsible for inspecting the quality of raw materials and finished products. All incoming material reports, sampling reports, and finished product inspection reports are prepared and maintained by this team. Our finished product inspection reports undergo dual reviews by both the quality control and business departments, ensuring that our products meet 100% of customer quality requirements.

02

Standardized Management

We strictly abide by ISO9001 and 6S management standards to ensure that we always meet high standards in quality management and production processes. As our valued customer, you can trust that our products consistently meet high quality standards while enjoying more competitive prices and faster delivery.

03

Complete Quality Inspection Process

We have established a comprehensive inspection process that we strictly adhere to, including raw material intake, in-process checks, and final product inspections. With over 40 tests ensuring production quality and more than 70 tests validating the final product, we guarantee that every aspect of our product meets the highest standards.

Our Commitment to Quality is Reflected in the Details

At every stage of production, we develop and adhere to detailed and necessary inspection items to ensure quality from appearance to performance. This gives us the confidence to be your reliable partner.

Process 1 —— Raw Material Inspection

For each batch of incoming materials, we conduct a quality inspection immediately upon arrival. We randomly select at least two samples from each pallet to check dimensions, appearance, surface treatment, and other critical factors. Materials that meet our standards are accepted into inventory, while those that do not are returned to the supplier.

Process 2 —— Production Inspection

We have established 40+ specific quality inspection standards for our self-produced light poles, fixtures, solar panels, and battery components. These standards ensure that dimensions and heights are within minimal tolerances, and that appearance, welding, and other parameters meet the exact requirements of each order.

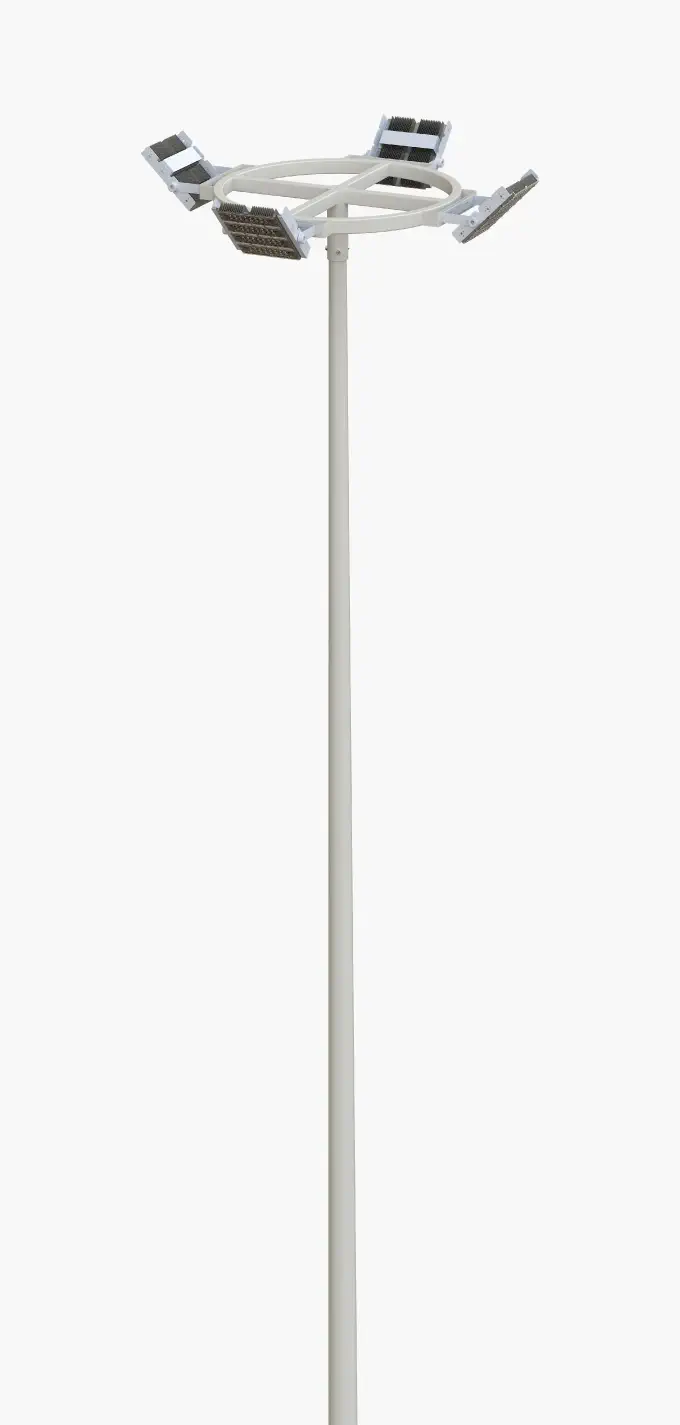

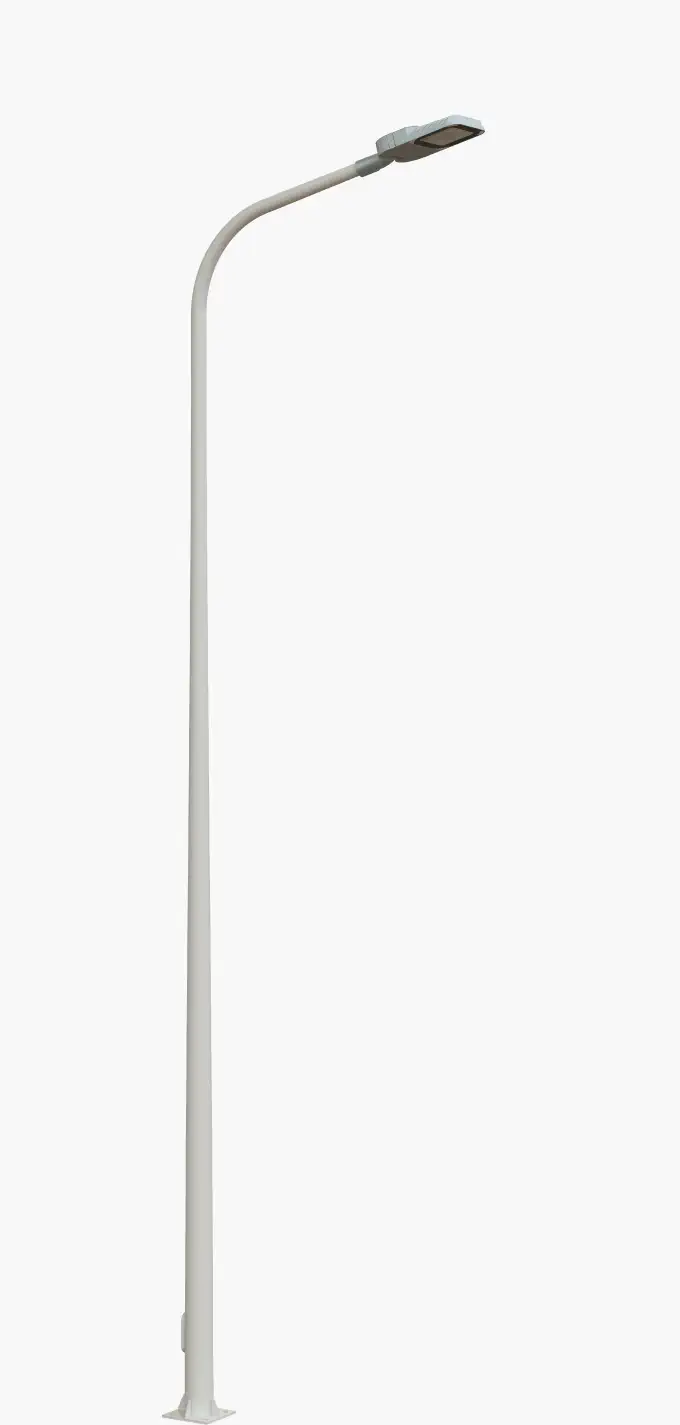

Light poles

We conduct thorough inspections to ensure flawless appearance, secure welding, and strict adherence to specifications. Pole height is accurate within ±5 cm for a 10-meter pole, diameter within ±2 cm for a 20 cm design, and wall thickness within ±0.5 mm for a 4 mm specification.

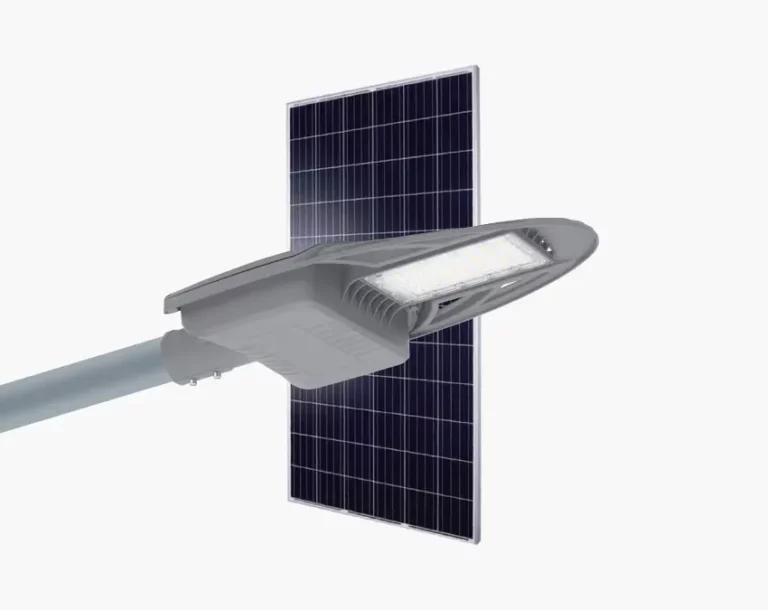

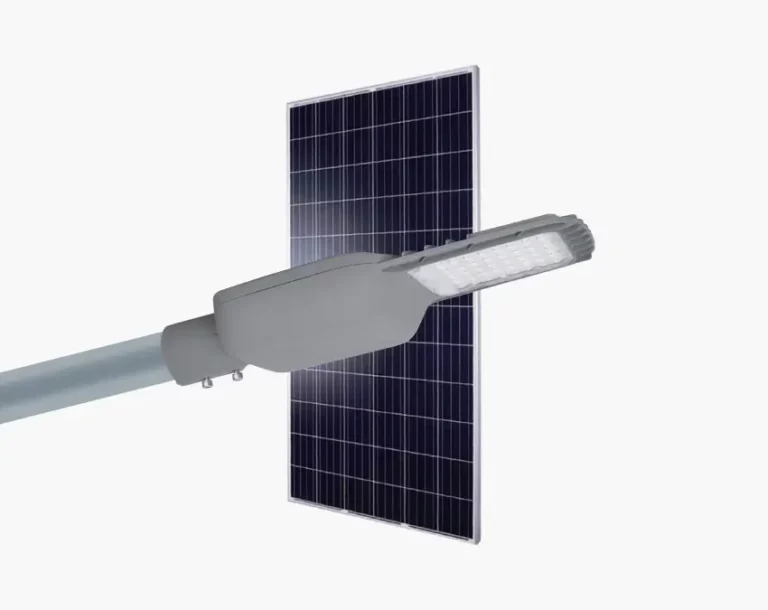

Fixtures

We inspect light fixtures for exterior damage, battery voltage, controller settings, charging/discharging, cover alignment, and overall appearance before packaging.

Solar panels

We check solar panels for cell integrity, welding quality, cracks, voltage, power, frame and junction box sealing, and overall appearance to ensure they meet order specifications.

Battery components

We sort battery cells by voltage and resistance, inspect welds, test charging/discharging for aging, and check the battery pack’s appearance and labeling for quality and compliance.

Process 3 —— Final Product Inspection

Our quality control process also includes 70+ final product inspections, covering appearance, specifications, and performance testing. Only products that fully

meet order standards are packaged and stored. For each component type, we’ve made specific quality criteria and employ random sampling to ensure the accuracy and reliability of our inspections.

Lean Manufacturing, Reliable Warranty

We manufacture key components (light poles, fixtures, solar panels, and batteries) in our own factory, using the industry’s best parts. This in-house production not only ensures strict adherence to quality standards but also allows us to offer competitive pricing and flexible customization options. We provide a 3-5 year warranty for the entire system, with a failure rate of less than 0.5%, maximizing your return on investment while minimizing maintenance costs.